You're Invited

Print Shop Pro® is a fully automated web-to-print management system designed exclusively for in-plant print shops and copy centers. You're invited to our webinar to learn more.

Download

Located in Springfield, Missouri, CoxHealth is the region’s only locally owned, not-for-profit health system. The organization comes from humble beginnings and was started in a frame house that was donated by a widow of a prominent lawyer on Thanksgiving Day in 1906. Today, CoxHealth is a five hospital system and is one of Springfield’s largest employers with more than 10,000 people employed throughout the system.

The CoxHealth mission is “To improve the health of the communities we service through quality health care, education and research.” CoxHealth is the only Springfield hospital named for five years in the U.S. News & World Report’s Best Regional Hospitals list. CoxHealth is also recognized by CareChex®, the medical quality rating division of Comparion®, as among the Top 10 percent U.S. hospitals for patient safety in overall hospital, medical and surgical care.

Print Shop Manager, Dan Morton and Document Management & Graphic Designer, Cory Mignard, sat down with us to give us insight into the people and equipment that are the heartbeat of the CoxHealth inplant print shop operation.

Dan has been with CoxHealth for 11 years as the Print Shop Manager. He is originally from Lakeside, California, a stones throw from edu’s corporate headquarters in San Diego. Dan began his career working for the Xerox Corporation in San Diego. He worked hands on for 9 years in technical service and spent another 11 years at Xerox in management. Prior to CoxHealth he worked for IKON (now Ricoh Corporation) in Springfield as a service technician and has been involved with printing equipment and also on the front lines of providing customer service for most of his career.

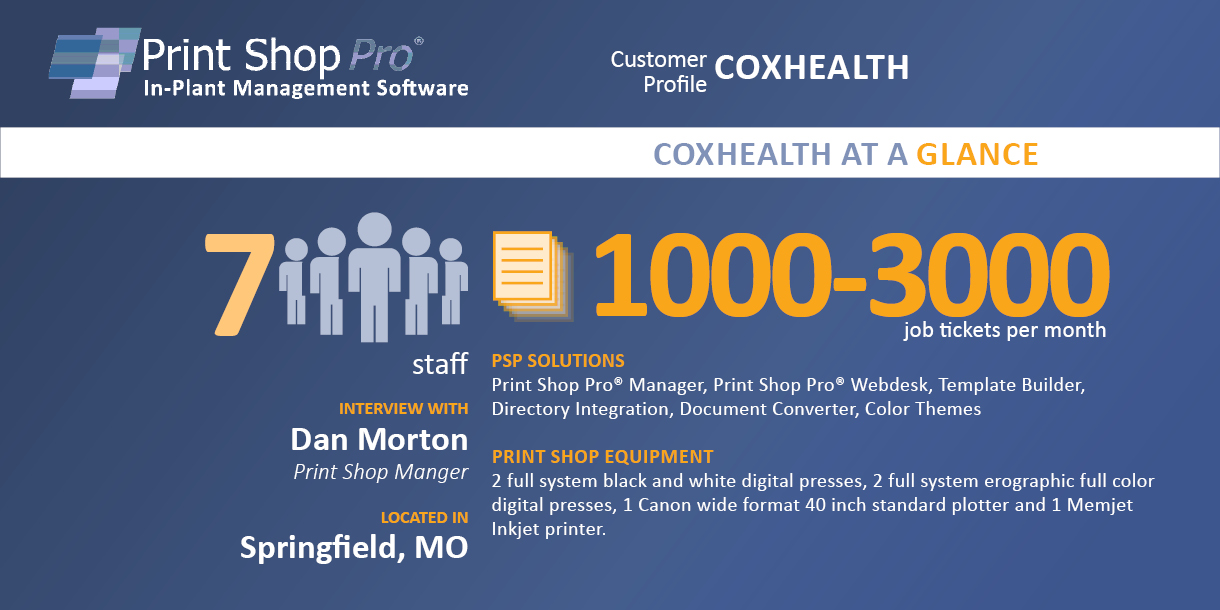

Cory is a native “Missourian” and has been with CoxHealth for 19 years. He is responsible for graphic design services and ensuring regulatory compliance within all printed materials. Cory helps enforce the organization’s internal design and brand standards. Printing Services consists of a team of 7… Dan supports 2 dedicated Document Management & Graphic Designers, 2 digital press operators who run all of the production equipment, and 2 finishing and bindery specialists who run all of the bindery equipment and handle shipping.

CoxHealth’s Printing Services Department primarily utilizes Xerox and Ricoh equipment. The shop’s equipment consists of 2 dedicated full system black and white digital presses, 2 full system xerographic full color digital presses, 1 Canon wide format 40 inch standard plotter and 1 Memjet Inkjet printer. They service internal customers exclusively. Dan shared, “Our department supports in excess of 10k+ employees across 400 departments and 60+ locations throughout Southwest Missouri, so we’ve got our hands full.”

When asked about the types of jobs they manage, Dan and Cory shared, “Print jobs have evolved. 10+ years ago most of our jobs were analog flatsheet handwritten medical forms. Today, most medical records are digital forms that are populated at the point of use. So, now we’re primarily printing a lot of color collateral marketing materials like brochures, educational and training materials as well as business cards, stationery, envelopes, mail merges and books, all with the support of Print Shop Pro® (PSP).” Cory added, “We also offer wide format printing and we’re unique in that we have a full service bindery with folding, cutting, drilling, spiral binding, padding, packaging, shipping and job delivery solutions.”

When asked about some of the unique challenges the shop faces being in the medical industry, Dan shared, “The environment of the medical industry changed dramatically starting about 5 years ago with the launch of the Affordable Care Act (ACA), it has put a financial squeeze on the medical industry. The focus of everything we do is with customer satisfaction and expense control in mind. We have to keep customers happy and we have to keep expenses down. This is one of the initial reasons we looked at PSP. Its affordability, in addition to edu’s production model with the ability to configure jobs to run multiple up, we could really see right away how it could help us to reduce costs.”

The shop processes 1,100 jobs per month totaling roughly 800k+ impressions per month. This number is down from 1 million impressions per month just 11 months ago. Dan explained, ”This is due to some of the efficiencies PSP has forced us into. We have made extensive use of the online store in PSP. We loaded our full catalog of forms and made them available in the online store. A customer can place an order via the store and automatically have it converted into a print order. We then ignore the store order. A contingency of our agreement to move forward with edu was their Development Team creating the integration between store and print orders. edu built this integration specially for us. As we all know, clicks and materials costs money. Converting a store order into a print order allows more jobs to be run multiple up, saving us on the costs of materials and click charges. And, we can pass those savings on to our customers increasing our value to the organization.”

CoxHealth purchased PSP in February of 2016. And,

though CoxHealth hasn’t been a long time customer, Dan shared, “We officially turned on PSP October 1, 2016 to coincide with the start of our fiscal year. Effective that day we immediately saw a change and improvement in our work model as well as increased efficiency in our number of impressions.”

The CoxHealth Printing Services Team anticipated there would be challenges transitioning to a new system including the learning curve associated with learning any new technology. They were switching from an internally built system that had been in place for 17+ years. “Our old system was built during our analog flat sheet printing days when there was a lot of press activity. It was built around tracking inventory, paper and press run time. As the nature of our print jobs changed, we found ourselves lacking flexibility within the old software. Plus, the platform it was running on was at its end of life which forced us to start shopping systems,” Dan shared.

When asked why they chose PSP of all the systems they looked at Dan shared, “edu has been great to deal with and PSP had the flexibility to easily fit our needs. The team at edu was always responsive and addressed our questions immediately. Cory added, “Another large deciding factor that attracted us to edu was the feeling of support we got from day 1 when we first made contact and the quickness in which edu personnel would get back and provide solutions. Mike and Chuck were always really good at listening and taking the time to really get what we needed and were very open and receptive to our ideas. And though we don’t always get what we want, we always got what we needed. Our ideas were met with excitement which was the exact opposite of the response we received from every other vendor we met with.”

Dan and Cory also shared their process for rolling out PSP. Dan shared, “After dragging our feet for a few months our management directed us to get PSP up and running October 1, giving us just two months to get the system configured and launched. We went into a bit of a panic trying to get things jammed together but edu was there with us the whole time holding our hand and guiding us through the process. They configured our initial catalog products. As jobs came in we would build clones and publish them in the store. For the first few months it was a full time job getting all of the forms into the system. Today we have over 12,000 items in our online catalog with a re-order number.” He continued, “Our customers were coming from using a single page web form that had one field for special instructions. They couldn’t attach any files and would send that to us in an email. Now, customers have a full service online store with templated business cards and they can order anything they want. It was a little overwhelming to begin with but now they love PSP. Customers love the automated emails. This has driven a lot of happy customers. They also love the fact that they know immediately when an order is complete and they are notified immediately of any issues such as copyright concerns. This has greatly reduced the number of calls we get.”

Outside of printing, both Dan and Cory enjoy the outdoors, hiking, camping, scenic drives and traveling to local lakes. Dan shared, “Missouri is a well kept secret. There are some really beautiful lakes and state parks. We’re just north of Branson on a chain of three major lakes. It’s a great place for family entertainment and we love it.”

Recent Comments